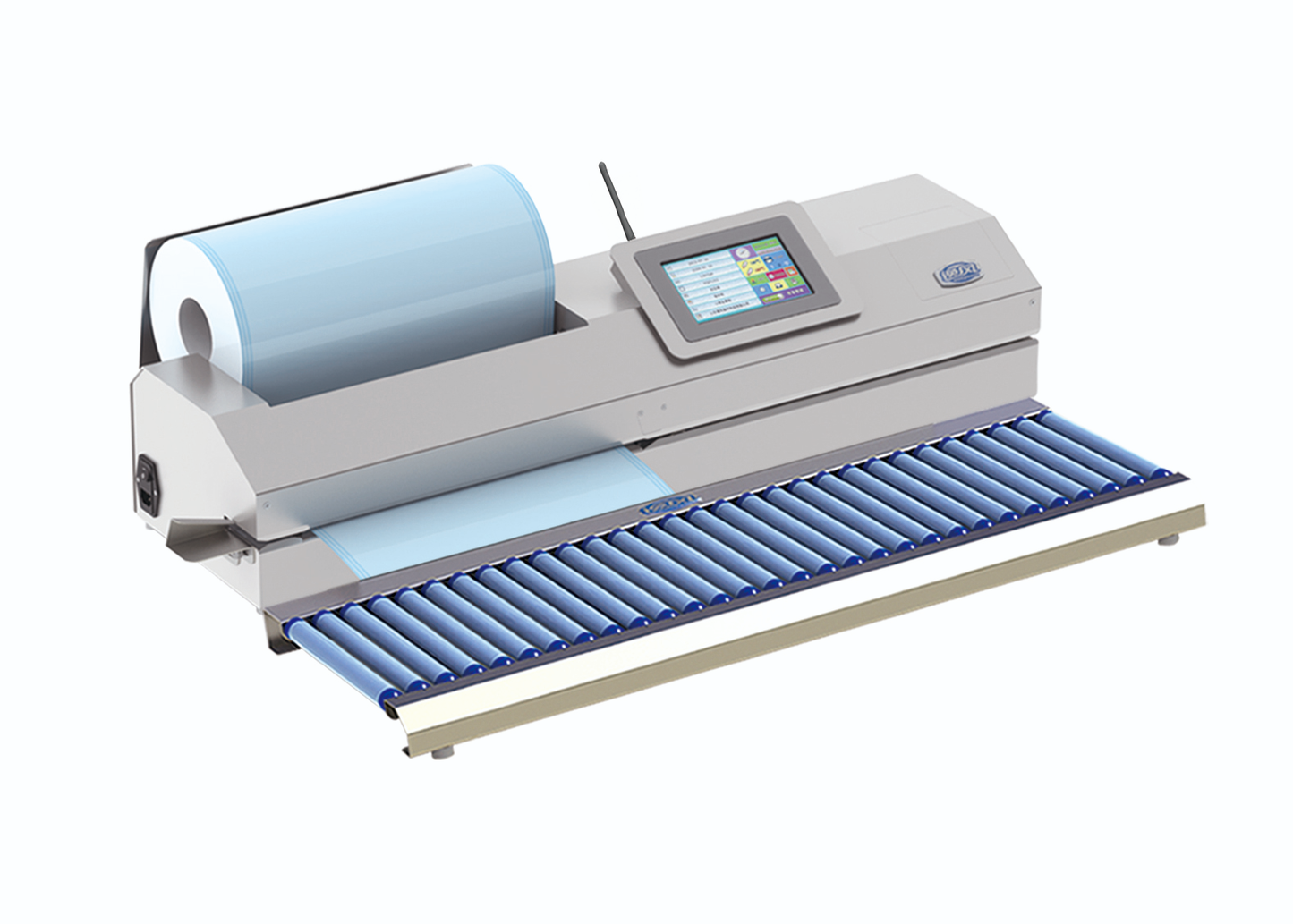

SD121-A Automatic Thermal Sealing Machine

SD121-A Automatic Thermal Sealing Machine

SD121-A Automatic Thermal Sealing Machine

Brand: SADA Medical

Model NO.:SD121-A

Product Origin:China

Functions: cutting, sealing and printing in one, capable of cutting or sealing and printing separately

Technical parameters:

1. Control system: 7-inch LCD capacitive touch screen, graphical operation interface, built-in clock/calendar and working parameter adjustment and setting, counting function, full Chinese display, Android operating system.

2. Cutting length: ≥50mm

3. Cutting speed: 18±0.5m/min

4. Cutting accuracy: ≤1%

5. Cutting width: ≤400mm (multiple rolls can be cut and sealed at the same time)

6. Sealing speed: 10±0.5m/min. Light control technology is used to achieve automatic detection of sealing and printing.

7. Sealing margin: 0-35mm adjustable

8. Indentation width: 12mm, sealing indicators meet the requirements of the standard "YY/T 0698.5-2009"

9. Working temperature: 60~220℃ adjustable

10. Sealing pressure: 85±30N

11. Temperature control accuracy: ≤1%, with built-in overheating protection function.

12. Printing method: dot matrix printer

13. Working environment: 10~40℃

14. AC power supply: 220V±10% 50Hz

15. Power: 600W

16. Maximum current: 3.2A

17. Fuse: 5A X 2

18. Weight: 46kg

19. Equipment size: 1090×290×200mm

20. Roller size: 1100*286*52mm

21. Shell material: 304 stainless steel

Functions:

1. It has the function of automatic paper feeding, cutting, sealing and printing. You only need to set the required length and quantity of paper and plastic bags according to actual needs. After starting the program, the equipment can complete automatic paper feeding, automatic cutting, automatic heat sealing, and finally complete the Chinese and English printing of the set parameters;

2. It can load multiple rolls of paper and plastic bags of different widths at one time according to actual needs, and realize cutting and sealing of multiple rolls at the same time, so as to improve the working efficiency of the machine;

3. It has the function of independent paper and plastic bag cutting, independent heat sealing or sealing printing, or integrated cutting, sealing and printing, which can realize multi-purpose of one machine and effectively improve work efficiency;

4. 7-inch LCD capacitive touch screen, built-in Andriod operating system, graphical operation interface, built-in clock/calendar and working parameter adjustment and setting, and automatic storage function; it can store more than 8 million print information records

5. You can set or change the various parameters of the equipment through the built-in 7-inch touch control screen, and the corresponding setting content will be printed by the sealing machine at the same time. 6. The working temperature can be set arbitrarily from 60 to 220℃, with a temperature control accuracy of ±1%; 6 common temperatures are preset, 60, 100, 120, 160, 180, and 220 degrees, which can be quickly switched according to the daily needs of users to meet the needs of fast-paced work.

7. High-speed heating design: It only takes 20s to heat up from room temperature to 180℃, which is highly efficient and energy-saving and meets the needs of fast-paced work;

8. Auxiliary cooling design: It is equipped with a microcomputer-controlled cooling system to reduce the waiting time when adjusting the temperature from high-temperature sealing to low-temperature sealing;

9. Safety: If the sealing temperature exceeds the working temperature setting range of ±4℃, the machine will automatically stop working, effectively ensuring the quality of sealing and the safe operation of the equipment.

⭐10. The equipment has material shortage alarm, roll bag blocking, wrinkle alarm, automatic detection of working engineering, and automatic fault alarm prompt.

11. It has energy-saving function, and can adjust the standby time. When the equipment is not in use, it will automatically cool down to the standby temperature to save energy.

12. Automatic energy-saving standby: adjustable standby time and standby temperature, intelligent standby recovery, photoelectric induction roll bag feeding can be restored to working temperature at high speed

13. Automatic detection function for sealing machine operation identification, to detect the operating pressure and speed of the equipment, the parameters of the equipment itself can be displayed in real time, and the speed, pressure, temperature and test time of the equipment can be printed and saved in the test state;

14. Chinese and English, numbers and special symbol printing functions in accordance with "YY0466-2003 Medical Devices for Medical Device Labels, Markings and Information Provision Symbols" can realize the expiration date, batch, name of the department using, operator name or code, pot number, pot number and other printing requirements required by the specification; the printing function can be turned on or off with one click, or a certain item can be turned off at will for selective printing, and the CE mark can be selected for printing.

15. Time and date are automatically updated every day. Sterilization date and expiration date can be automatically adjusted according to the settings. When printing, leap month and big and small month are automatically adjusted to ensure the consistency of the actual set days. There is no need to manually adjust the number of days per month due to big and small months.

16. It has three printing font selection forms: narrow, normal and wide. At the same time, it is combined with the printing form of symbols to facilitate printing more content on relatively narrow bags. The system will give the printing width value according to the selected printing content, automatically calculate the minimum printing width, and realize the reminder before sealing when the width of the paper-plastic bag is insufficient.

17. It has a Chinese and English printing system for the sealing machine, a built-in 24-pin printer, clear printing, and easy and fast setting of printing items;

18. The printing function can be turned off with one click, and a certain item can be selectively turned off as needed, which is convenient for the operator to quickly switch between printing and not printing;

19. The upper opening can change the color ribbon, which is more convenient and quick.

20. It can store more than 8 million print information records, and can query the historical data of cutting and sealing, and export the data to the computer.

⭐21. It has a laser beam monitoring function. If it detects the deviation of the bag, it will stop automatically, which can effectively prevent the bag from being rolled into the equipment during the cutting process.

22. It has a printing parameter layout function, and can adjust the printing order and printing items of the parameters at will.

⭐23. It has a wireless networking function and a USB interface, which can import data into the sealing machine, or export it to the computer, and generate relevant statistical tables

24. It is equipped with a roller workbench, which makes the work smoother and more convenient.

After-sale Service: 1 year quality guarantee; Question response within 24 hours; Video or photos instruction guide.

SADA MEDICAL Quality Standards:

ISO 9001:2015 Quality Management Systems

EN ISO 13485:2016 Quality Management System - Medical Devices

CERTIFICATES:

SADA MEDICAL Workshop:

Video of SADA MEDICAL Autoclaves:

Catalog, Brothures and User Manual Please refer below Link:

https://www.sadamedical.com/pages/catalog-download

Sada Medical is a professional supplier of steam autoclaves, low temperature plasma autoclaves, ethylene oxide sterilizers, we have exported to all over the world with affordable prices.

If you're interested in our products, please feel free to contact us by Below Contact Form, looking foward to hearing from you soon.